Meet the AON3D Hylo

AON3D’s new flagship industrial 3D printer, powered by Basis™. Driving increased automation, advanced process monitoring, optimised part quality, and verifiable printed part quality.

Industry-Leading Performance

Print the world’s strongest and most advanced polymers, including composites, while machine learning optimises process parameters to achieve the highest-performing parts possible.

Turnkey Simplicity

A fully automated experience coupled with smart software reduces the inherent complexities of printing high-performance polymers and new 3rd party materials.

Build for Production

Manufacture more parts and bigger designs with unmatched throughput and tools that speed time to validate parts.

AON3D Hylo’s Key Features

Massive 250°C Build Chamber

Print more parts and larger parts with an actively-heated, precision-controlled 650 x 450 x 450mm build volume.

Advanced Material Management

Hylo features a humidity controlled storage bay with automated material loading/changeover capabilities and filament diameter detection and compensation.

Independent Dual Extrusion

Independent, self-leveling, and composite-ready extruders enable multi-material, soluble support, and duplication mode printing.

In-Process Monitoring

With 25+ integrated sensors, Hylo’s advanced process monitoring logs enable printed part quality verification, hidden defect identification, and aids in part qualification.

Materials

Base Polymers

ABS

ASA

Nylon (PA6, 6/66, 11, 12)

PAEK

PC

PEEK

PEI (ULTEM 9085, 1010)

PEKK

PETG

POM

PP

PPSU

PSU

PVDF

TPE

TPI

TPU

and more

Composites

CF ABS

CF PA

CF PC

CF PEEK

CF PEI

CF PEKK

CF PETG

CF PP

ESD ABS

ESD PA

GF ABS

GF PA

GF PETG

GF PP

and more

Supports

Aquasys 120

Aquasys 180

High Temp Support

HIPS

PEI Support

PVA

and more

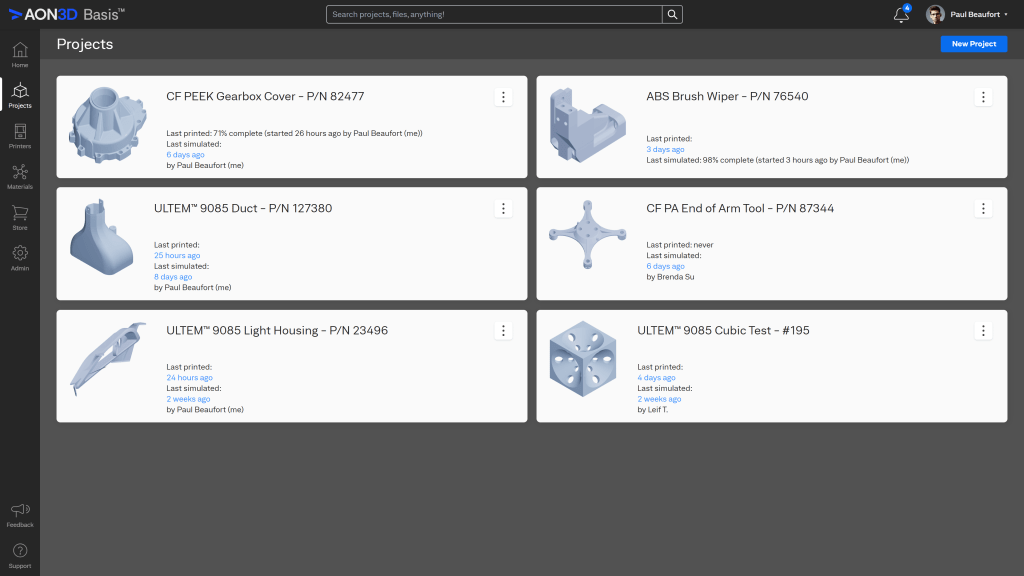

AON3D Basis™

Manage projects and printers, optimise part properties with machine learning, and verify printed part quality with AON3D Basis™.

Manage

Gain complete control of the additive manufacturing process across printers and facilities.

Optimise

Print right the first time while maximising part properties with machine-learning optimisation.

Qualify

Unlock new methods of non-destructive part examination, reducing downstream quality management burdens.

Ready to explore the AON3D Hylo further?