3D Printing Technology: Stereolithography – SLA

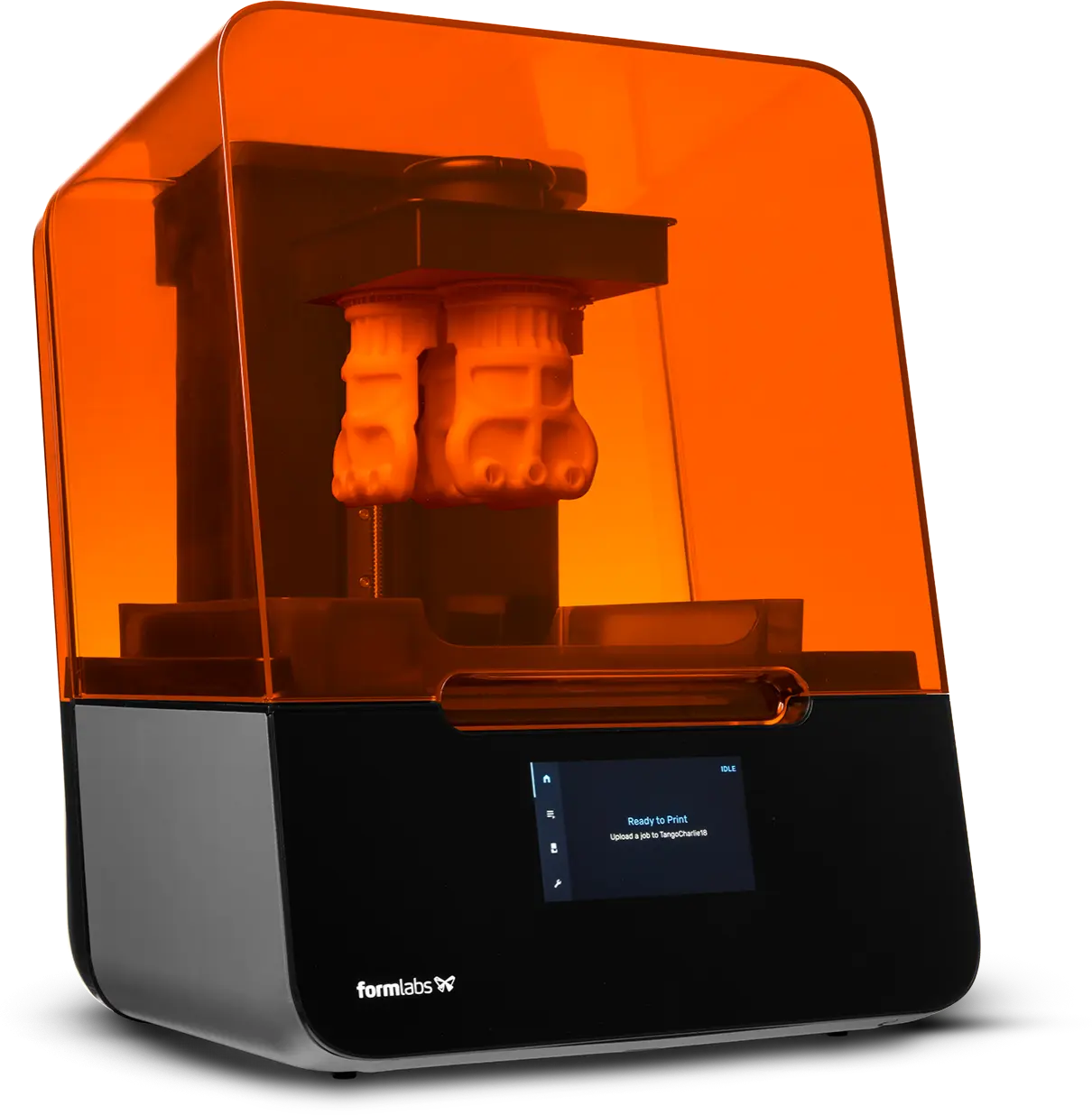

Stereolithography, SLA in short, is an additive manufacturing method to create 3D models, parts, and prototypes. SLA is one of the oldest technologies, and in principle, has a process that is very similar to Digital Light Processing (DLP). To find out more about DLP, you can check out our article on it here.

How Does SLA Work?

The build plate is placed in a vat of polymer resin after which a UV light is focused to draw the desired design. When the UV light hits the photosensitive resin, it begins to solidify the resin layer by layer. As most of the SLA printers prints the model upside down, the build plate slowly rises higher and higher until the part has been fully printed.

If you are wondering how the UV light is controlled, a laser, galvanometers, and a series of mirrors are the parts that are controlling the pathing of the laser.

The laser’s pathing starts off as a CAD 3D Model. The file is then converted to a STL file format. After which it must be sent to a 3D Slicer Software. This would create a G-code for the movement of the laser which is the native language of the 3D printers.

What Material Does SLA Use?

As the material is required to be liquid, thermoset polymer, or other known resins, are used for this process. However, there are many different types of resins:

- Standard Resins

- Engineering Resins,

- Dental and Medeical Resins

- Castable Resins.

For a more in-depth look on the different type of resins materials, click here.

Advantages

High Accuracy and Detailing

SLA printers have some of the best accuracy in comparison to the rest of the additive manufacturing technologies. This allows for very tight dimensional tolerances, to as little as 0.1mm. This allows for thin walls, sharp corners, and complex geometrical shapes to be created while maintaining a smooth surface finishing for the print.

Very Matured Technology

SLA technology has been used in this industry for a very long time. The process has been refined over the years with a very stable process and many different machine suppliers. Giving you the ease of mind that if you ever require assistance, it is not too far away.

Disadvantages

High Cost

The initial cost of the SLA machine is high, starting at SG$4500. This is significantly higher as compared to budget FDM machines, where it can cost 10 times less with the same build space.

Besides that, the cost of the material is high, costing almost SG$200 – SG$250 per litre of resin material.

The post-processing of SLA parts also requires other equipment which drives up the initial cost of owning the machine.

Post-Processing

Unlike FDM machines, 3D printed SLS parts have to first be cleared of the excess liquid resin which depending on the print, may be in small crevices and holes making it difficult to clean. In addition to liquid resin being messier to deal with, the supports also require additional time to be removed.

Material Has Limited Properties And Colours

Although there are new types of resins in development to counteract this problem, there is still a long way to go in terms of stronger mechanical properties as compared to the other 3D printed parts using different technologies. There is also a limitation in colours which affects the aesthetics of the piece and may be an important factor to certain people.

Speed

SLA is able to 3D print parts with high precision and a good surface finishing at a relatively fast speed. However, they are able to go faster than other 3D printing processes like FDM at the sacrifice of quality.

Get your parts 3D Printed today! Need help to decide? Contact us and we will get back to you.

Some links to articles are not live yet, please be patient while we continuously update our site with new articles and this post if there are any new developments.